● The high-performance, multi-purpose UV laser cutting machine apply non-contact working platform and equipped with high speed digital galvanometer to avoid the hidden damage caused by the stress processing of tool and molds;

● The function of CCD automatic positioning compensation deformation can be more suitable for product deformation, and the function of high configured automatic edge cutting automatic compensation can adapt to the deviation caused by stress processing of previous process, and the cutting edge is more smooth.

● With the feature of short wavelength, high energy density, small heat influence range,The 355nm UV laser able to achieve cold process by destroy material molecular structure quickly,eliminate the cooling water, cleansing water, cutting and dust along with mechanical processing.

● It can identify DXF and GERBER files and eliminate molds,achieve rapid prototyping, cutting and drilling, especially suitable for the processing of complex, sophisticated and difficult products.

● The design of duplex station saves the time of replacing the material by manual or automatic manipulator, which exceeds 30% of the laser efficiency of the same type of equipment in the market.

● With the design of flight optical path, the high-speed mobile gantry structure, can be customized to carry automatic loading and unloading machine, or match with SMT line

● Mobile camera module sub-board, fingerprint identification module cutting, TF card type memory card, FPC flexible circuit board; cutting any product within thickness of 1MM has no burr ,high precision and small heat affected range;

● Self-developed control software based on WINDOWS, fool operation, simple and quick.

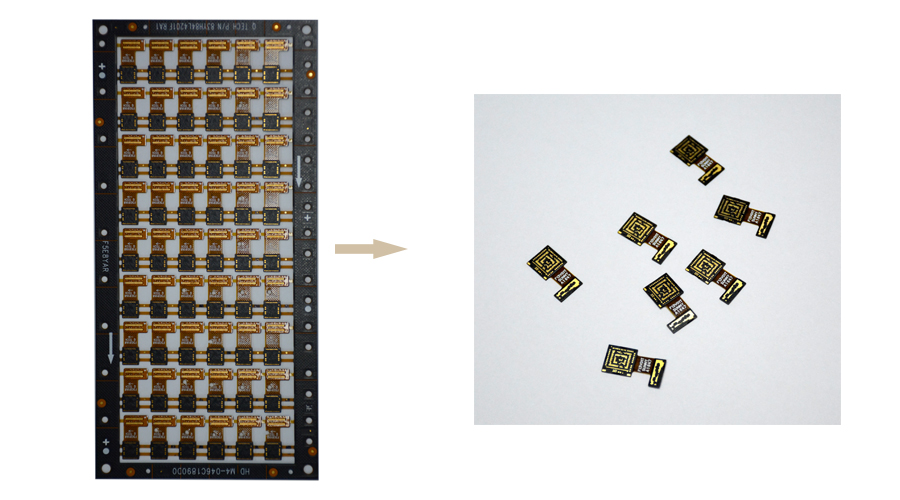

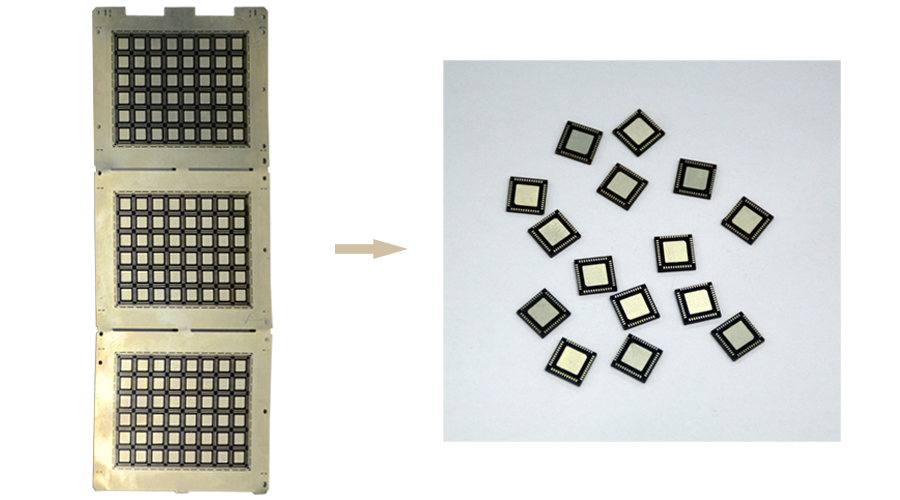

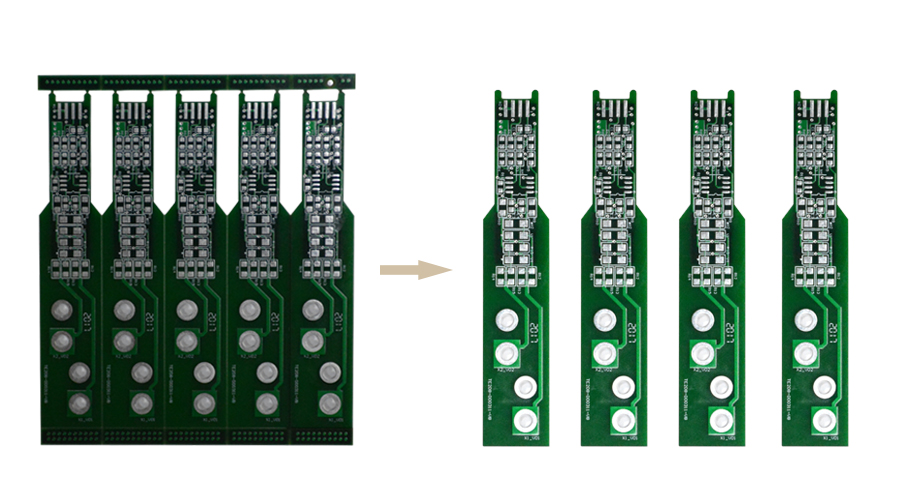

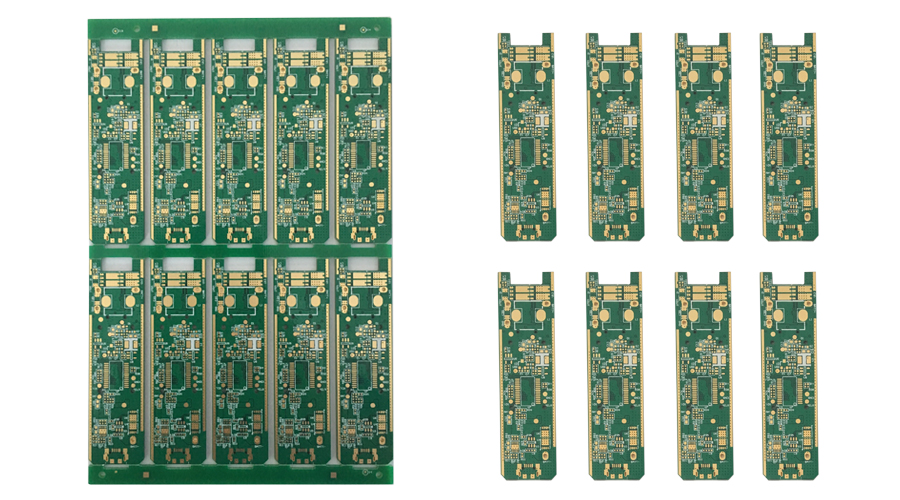

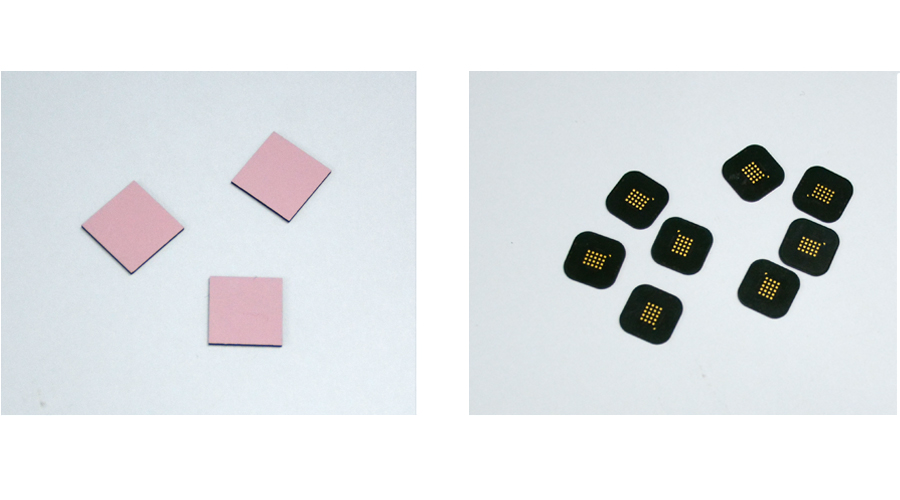

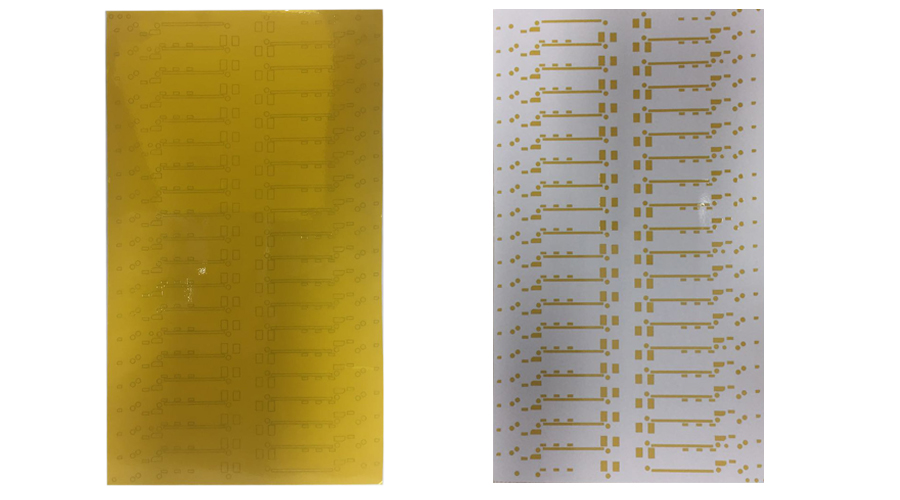

【Laser cutting sample effect】

Camera COB

PCB

PCB

Fingerprint identification module

CVL

FPC